Fast Delivery

30 days express delivery

Our bespoke hydraulic solutions include the customizable P80-U78-1OT directional control valve, designed to meet the specific requirements of our global customers. This valve offers exceptional performance with a rated flow of 80 L/min, max pressure of 250 bar, and a wide operating viscosity range. It is suitable for various applications in material handling, construction, agriculture, and industrial vehicles.

| P80 Series Monoblock Directional Valve Parameters | |

|---|---|

| Spool | 1 Spool, 2 Spool, 3 Spool, 4 Spool, 5 Spool, 6 Spool, 7 Spool |

| Control Method | Manual, Pneumatic, Electro-pneumatic, Electro-hydraulic, Solenoid, Hydraulic, Hydraulic and Manual, Cable, Joystick |

| Section | 1 Section, 2 Section, 3 Section, 4 Section, 5 Section, 6 Section, 7 Section |

| Ambient Temperature Range | -40°C to +80°C (-40°F to +176°F) |

| Operating Viscosity Range | 15 - 75 mm²/s (15 cSt to 75 cSt) |

| Max Pressure | 315 bar (4600 psi) |

| Rated Flow | 80 L/min (21.2 US gpm) |

| Structure Type | Monoblock valve |

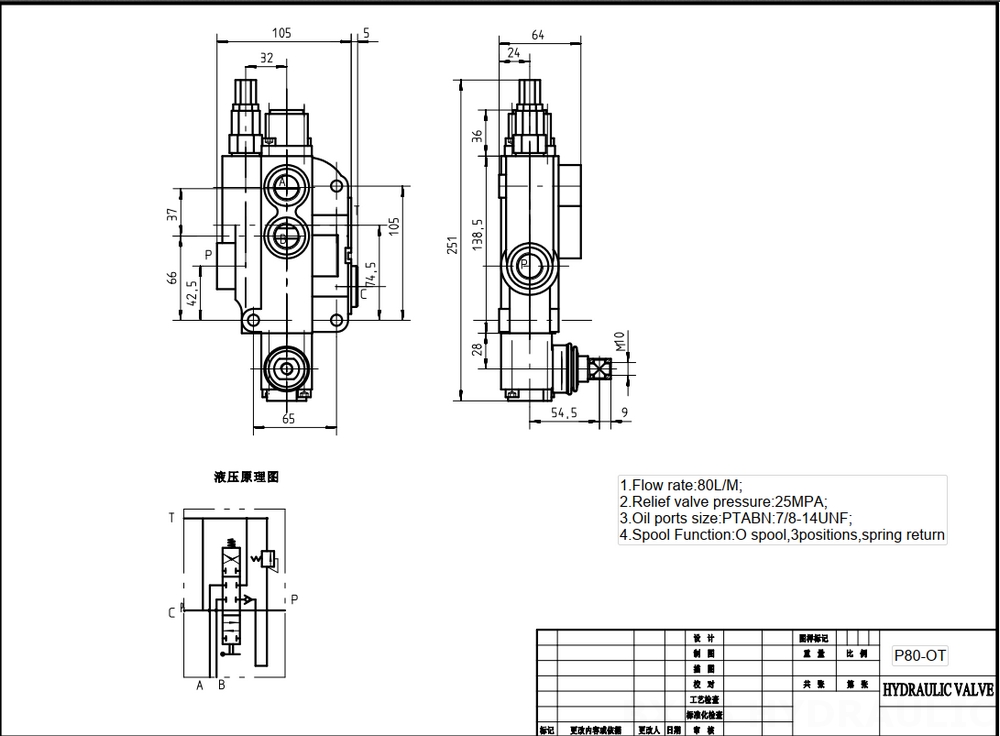

**P80-U78-1OT Directional Control Valve**

**Control Method:** Manual

**Section:** 1 Section

**Structure Type:** Monoblock valve

**Rated Flow:** 80 L/min (21.2 US gpm)

**Max Pressure:** 250 bar (3600 psi)

**Operating Viscosity Range:** 15 - 75 mm²/s (15 cSt to 75 cSt)

**Ambient Temperature Range:** -40°C to +80°C (-40°F to +176°F)

**Spool:** 1 Spool

**Series:** P80 Series

**Applications:**

The P80-U78-1OT directional control valve is widely used in various applications, including:

- Material Handling: Telehandlers, forklifts, stackers, aerial platforms

- Construction and Earth Moving: Motor graders, excavators, skid steer loaders, compact wheel loaders

- Agriculture: Tractors, harvesters, sprayers

- Industrial Vehicles: Cranes, aerial work platforms, mining equipment

**OEM/ODM/Private Label Services:**

We offer flexible OEM/ODM/Private Label services to meet the unique requirements of our customers. We can customize the P80-U78-1OT directional control valve according to your specifications, including:

- Custom porting configurations

- Specific pressure and flow requirements

- Integration with other hydraulic components

- Your company logo and branding

Our team of experienced engineers will work closely with you to develop a customized hydraulic solution that meets your exact needs and exceeds your expectations.