Fast Delivery

30 days express delivery

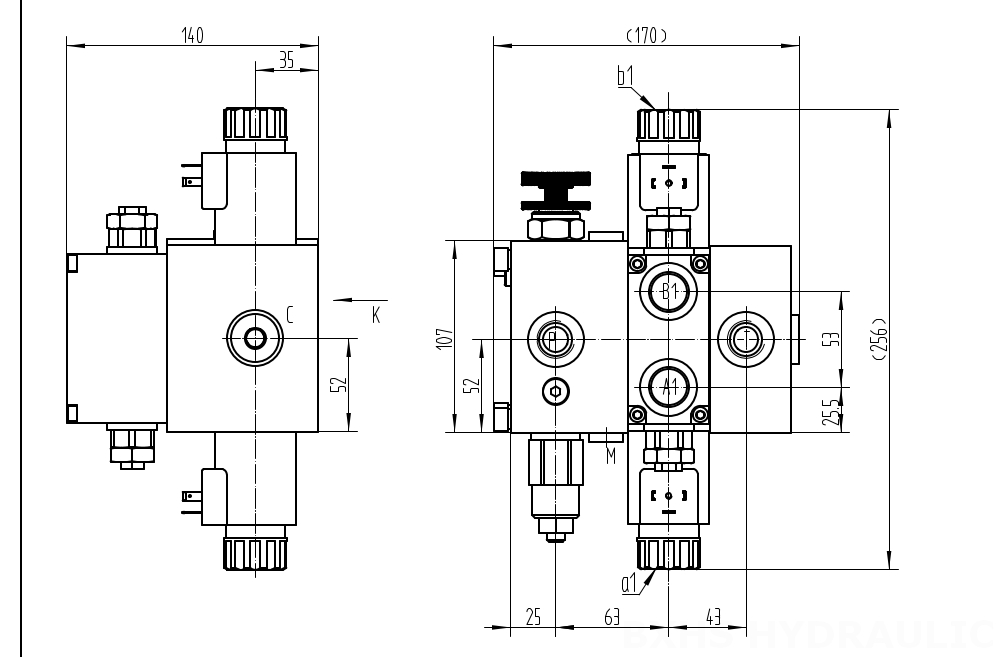

The DCV58F Solenoid 1 Spool Sectional Directional Valve is a high-performance hydraulic valve designed for a wide range of industrial applications. With its robust construction, reliable operation, and customizable options, it offers a versatile solution for controlling fluid flow in hydraulic systems.

| DCV58F Series Sectional Directional Valve Parameters | |

|---|---|

| Control Method | Solenoid, Solenoid And Manual |

| Spool | 1 Spool, 2 Spool, 3 Spool, 4 Spool, 5 Spool, 6 Spool, 7 Spool, 8 Spool, 9 Spool, 10 Spool, 11 Spool, 12 Spool |

| Rated Flow | 60 L/min (15.8 US gpm) |

| Max Pressure | 350 bar (5100 psi) |

| Inlet Port | G1/2, M22×1.5, SAE 10, 1/2 NPT |

| Outlet Port | G1/2, M22×1.5, SAE 10, 1/2 NPT |

| Port Size | G1/2, M22×1.5, SAE 10, 1/2 NPT |

| Section | 1 Section, 2 Section, 3 Section, 4 Section, 5 Section, 6 Section, 7 Section, 8 Section, 9 Section, 10 Section, 11 Section, 12 Section |

| Structure Type | Sectional valve |

| Ambient Temperature Range | -40°C to +80°C (-40°F to +176°F) |

| Operating Viscosity Range | 15 - 75 mm²/s (15 cSt to 75 cSt) |

Compact and modular design: Enables easy integration into existing systems and allows for flexible configuration. High flow capacity (60 L/min): Handles demanding hydraulic applications with ease. Durable construction: Built to withstand harsh operating conditions and ensures long service life. Versatile control options: Solenoid actuation provides precise and responsive control. Applications:The DCV58F Solenoid 1 Spool Sectional Directional Valve is ideal for use in a variety of hydraulic applications, including: Material handling equipment (forklifts, telehandlers, cranes)

,Construction and earth-moving machinery (excavators, skid steer loaders, wheel loaders), Agricultural equipment (tractors, harvesters, balers)

,Industrial vehicles (sweepers, waste compactors, hook-loaders)。

Customization Options:In addition to its standard configuration, the DCV58F Solenoid 1 Spool Sectional Directional Valve can be customized to meet specific application requirements, such as: Pressure and flow rate adjustments

, Alternative spool configurations , Integrated sensors and feedback devices

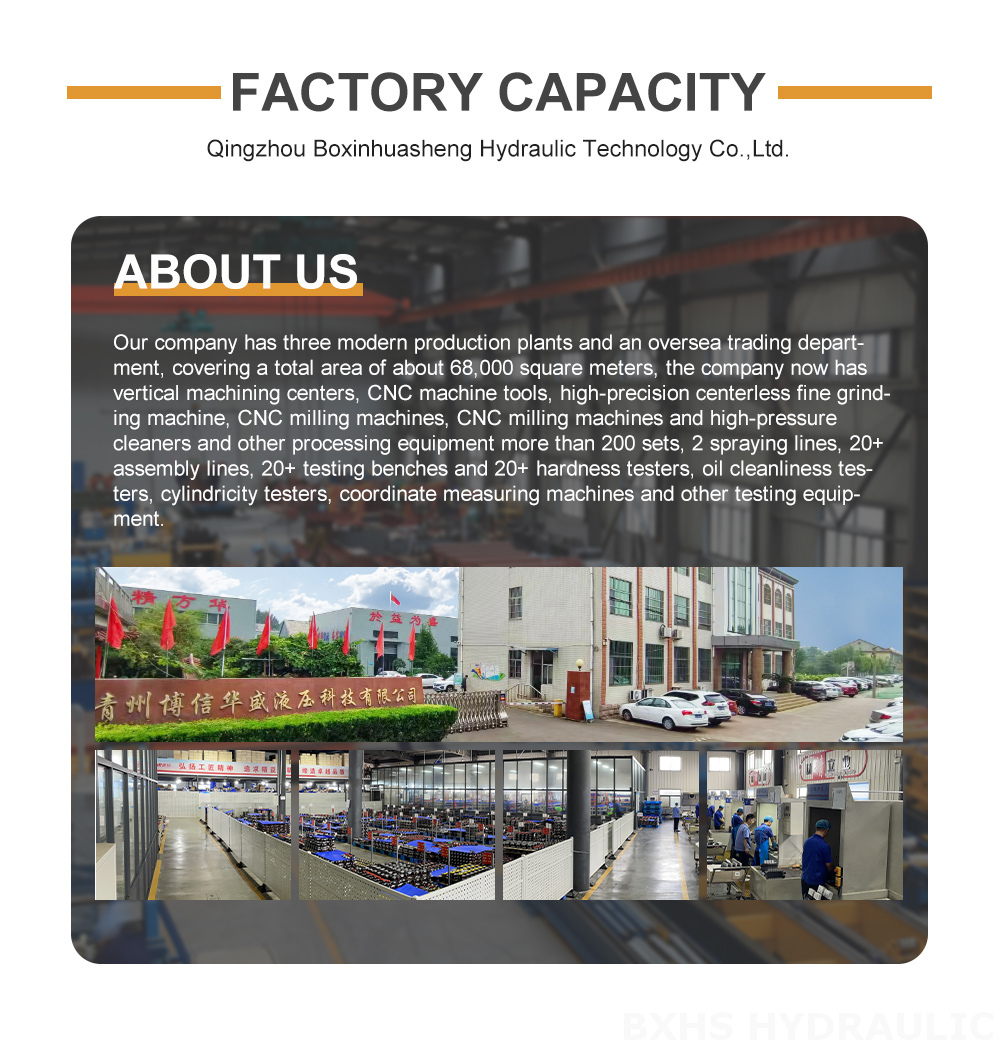

By partnering with our experienced engineering team, you can create a hydraulic valve solution that perfectly matches your unique needs.